NEWS CENTER

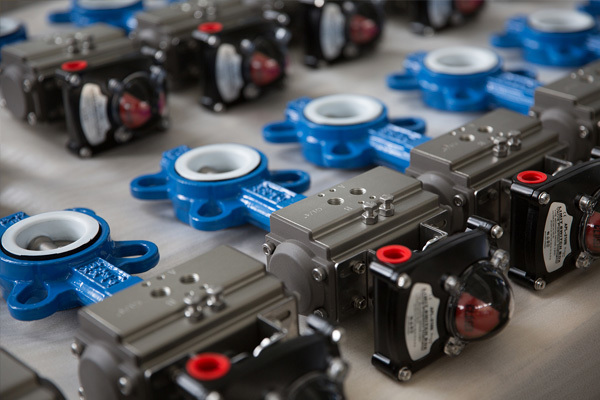

Common Faults and Troubleshooting Methods of Pneumatic Butterfly Valve

Release time:

2020-07-14

Wuxi Xinming Automatic Control Valve Co., Ltd. produces various pneumatic valves, including but not limited to pneumatic butterfly valves, pneumatic ball valves, pneumatic control valves and other products. Testing and adjustment of pneumatic butterfly valves for water treatment equipment 1. All parts of the butterfly valve, whether manual, pneumatic, hydraulic or electric, have been strictly debugged before leaving the factory. When re-checking the sealing performance, the user should evenly fix both sides of the inlet and outlet, close the butterfly valve, and apply pressure to the inlet side. Observe the outlet side for leaks. Before testing the pipe for strength, the disc should be opened to prevent damage to the seal pair. 2. Although the pneumatic butterfly valve has been strictly inspected and tested before leaving the factory, some products will automatically change the position of the screw during transportation, and need to readjust the pneumatic, hydraulic, etc., please refer to the instruction manual of the supporting drive equipment. 3. The opening and closing stroke of the control mechanism has been adjusted when the electric butterfly valve leaves the factory. In order to prevent the wrong direction when turning on the power, after the user turns on the power for the first time, please open the manual to the half-open position, and then press the electric switch to check whether the direction of the power is correct. The indicator plate is in line with the closing direction of the valve. Common faults and troubleshooting methods of pneumatic butterfly valves in water treatment equipment 1. Before installation, please confirm whether the performance of our products and the flow arrow of the medium are consistent with the working conditions, and the inner cavity of the valve should be inserted and cleaned. Before cleaning, do not allow foreign matter to adhere to the seal ring and butterfly plate. Close the butterfly plate to avoid damaging the sealing ring. 2. For butterfly valves, it is recommended to use special flanges, namely HGJ54-91 socket welded steel flanges for disc installation. 3. The installation position in the pipeline is vertical installation, not up and down installation. 4. The flow needs to be adjusted during use and controlled by the worm gear box. 5. For the butterfly valve with a large number of opening and closing times, please open the worm gear box cover within two months to check whether the butter is normal. Reserve on the right amount of butter. 6. Check the tightness of each connection part to ensure the tightness of the packing and the flexible rotation of the valve stem. 7. Metal sealing butterfly valve products are not suitable for installation at the end of the pipeline. If it must be installed at the end of the pipe, the outlet flange must be installed to prevent the sealing ring from overstocking or overpositioning. 8. The installation and use response of the valve stem Regularly check the use effect of the valve, and troubleshoot in time.

Related News